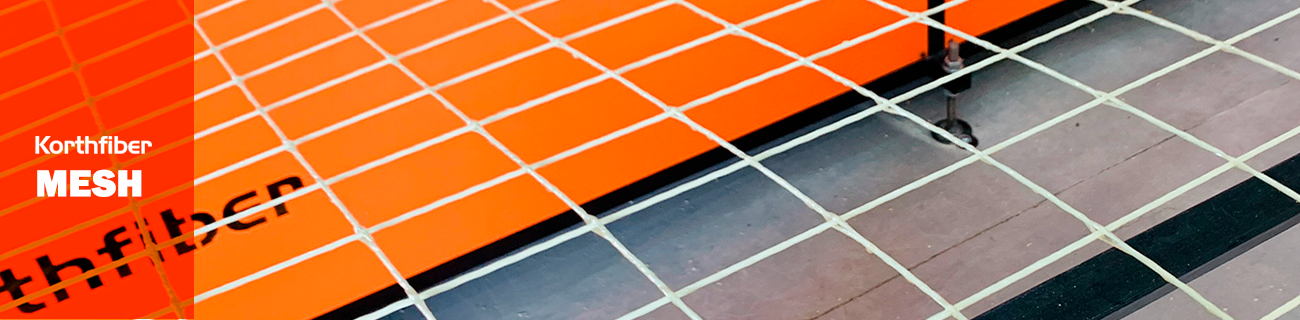

GFRP Rebar / GFRP Pop Mesh

KTF-Malha Pop is the first system for manufacturing screens (Malha Pop) in fiberglass developed in Latin America. Its production is compatible with market standards of 10×10, 15×15 and 20×20 centimeters. Its capacity is impressive, reaching 140m2 per hour.

- Traction speed of up to 180m² per hour

- 90-Strand Roving Yarn Shelf (4 Shelves)

- Manipulating wire passage structure (Wire passage frame - 1 per bathtub)

- Wetting tray with Plug And Play system Made in-house with AISI-304 stainless steel

- Wetting of wires by immersion

- Control of the amount of resin impregnated in the wire

- Design for ease of cleaning/access to the end of processes

- NR12 Touch Screen CNC Electrical Control Panel

- Voltage 220 V Three-Phase Current 50A - Consumption 15 Kw/h

- Real Time Speed Control

- Shelf tensioner

- Infrared heating system

- Cooling system

- Automated Flying Cutting System

| Manufacturing process: | Controlled fiberglass pultrusion |

| Production: | POP meshes of 10×10, 15×15 and 20×20 centimeters x infinite length |

| Structure: | Modular composed of 6 stages |

| Command: | CNC site with process control and operation in Real Time |

| Useful area: | 25 meters by 8 meters for manufacturing screens up to 3 meters wide |

| Line performance: | 140m2 per hour |

| Voltage: | 20V Three-Phase - 45 Kw/h |

| Operators per machine: | 3 operators |

| Guarantee: | 1 year |

Have a tank, pole or tube factory with the best equipment

of the company recognized worldwide for its excellence.

Speak to an expert: