We provide all the peripherals necessary for satisfactory production with Korthfiber equipment. We think of all the solutions so that your investment, whether in an individual line or even a larger and more complex system, meets all production demands.

KASPER DOSER

Kasper Doser is equipment developed to promote the storage and correct mixing of the liquid components necessary for the production of fiberglass profiles. The accessory is available in two versions, with a CNC programming system and a 100% pneumatic system.

| Doser - KASPER PNM | |

|---|---|

| Model: | DOS-KASPER-2C-PNM (Kasper 2-Component Pneumatic Doser) |

| Solids: | Possibility of dosing Solid particles (Powders and Fillers) |

| Command: | 100% Pneumatic - With Local or Remote control |

| Dosage Type: | Type Cut and Transfer |

| Component 1: | Dosage - 2.4 kg per cycle |

| Component 2: | Dosage – 0.5% to 6.0% per cycle |

MULTI PUNCH

The Multi Drill is a system made up of 4 drills in a 4 meter layout, useful for drilling the desired profile. With practical and interactive technology, CNC control makes programming and execution processes even easier.

| Multi Punch | |

|---|---|

| Model: | F-M-4B-4M-CNC (Multi Drill 4 Drills and 4 Useful Meters with CNC) |

| Axes: | 5 axes (4 Drill drive axes + 1 Linear Axis) |

| Control: | CNC - Interactive - Touch Screen |

| Useful area: | Up to 4000 mm Drilling Length - Ø 600 mm |

| Mandris: | Conical and Parallel up to Ø 600 mm |

| Command: | Location with Recipe Application and Speed Control in Real Time |

HIGHLIGHTER

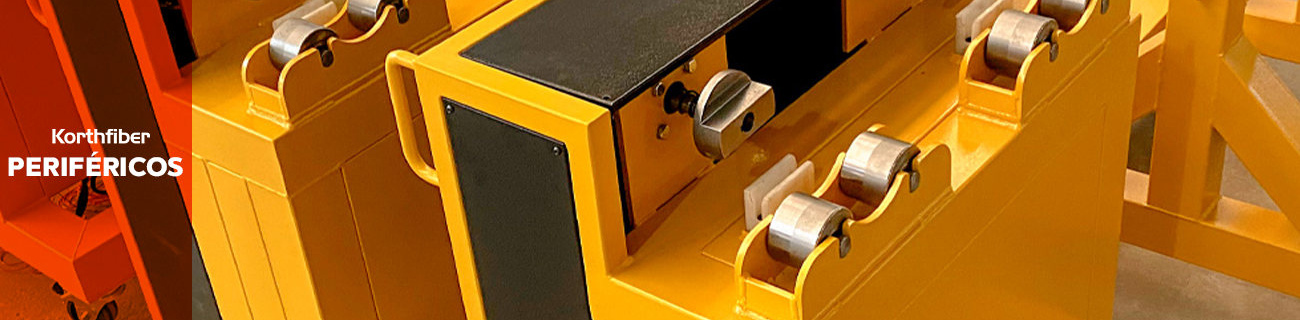

The Detacher enables the correct decoupling of the profiles manufactured in the mandrels. Focused on demolding profiles of up to 15 meters, this machinery ensures a continuous, standardized and safe production flow.

| Highlighter | |

|---|---|

| Model: | UNLOCKER-P&C-5MM-30T (Detached Para. & Conical - 600mm HID - 30 Ton) |

| Demolding: | 2 Pistons of 15 Tons Each with Safe Advance Control |

| Structure: | Robust carbon steel with electrostatic painting and locks |

| Locking System: | High Torque Positioning Locks for Heavy Mold Releases |

| Post Release: | Motorized Push System After Desoldering to Remove Profile |

| Command: | Location with Piston advance and return system and post-demolding motorization |

ROTARY CUTTING

Vertical saw makes up the line of machinery with the aim of finishing the manufactured profiles. With a useful area of up to 600mm and a rotating cutting function, this accessory will standardize your production.

| Orbital Serra Cut | |

|---|---|

| Model: | ORBITAL SAW CUTTING SYSTEM - C-PLC-SV-600 |

| Command: | PLC cycle control system - KORTHFIBER Panel |

| Cut: | Cutting by CONTINUOUS SAW - ORBITAL |

| Application: | Carry out cutting and trimming of fiberglass products - Posts, Tubes and others. |

| Command: | Remote, with speed and security controls |

| Structure: | Modular, and can be applied within KORTHFIBER standards |

OPERATION CAR (JOKER)

The Coringa Handling Cart is recommended for handling manufactured profiles. This carbon steel structure was designed to be resistant and eliminate the need for overhead cranes.

Promotes quick and efficient drying, reducing curing time by up to 40%.

| AUTOMATED handling and operation car "Joker" | |

|---|---|

| Model: | GIR-SEC-2P-GA (Spinner and Dryer with 2 Positions and Driven Rotation) |

| Command: | Simple motorized execution with reduction for dynamic movement |

| Practicality: | Easy handling, lightweight and does not require the use of overhead cranes |

| Application: | Rotates up to two mandrels and is manipulated manually |

| System: | Mandrel turning and movement system |

| Compact: | Compact system with independent counterpoint |

GEL COAT APPLICATOR

Developed to deliver the best finish for posts and tubes. Automatically distributes the exact proportion of Gel Coat and catalyst, reducing application costs and generating greater speed in the process.

| Gel Coat Applicator | |

|---|---|

| Model: | GEL COAT-2P-PRESS (Gel Coat Applicator with 2 Pressurized Positions) |

| Command: | Simple implementation with frequency inverters for two-way painting |

| Practicality: | Paints up to two mandrels simultaneously |

| Application: | Used for applying Gel Coat for external painting on Posts and Tubes |

| System: | Application system with Gel Coat, Catalyst and Solvent (Cleaning) |

| Pressurized: | System with pressurization of items for Painting |

Have a tank, pole or tube factory with the best equipment

of the company recognized worldwide for its excellence.

Speak to an expert: