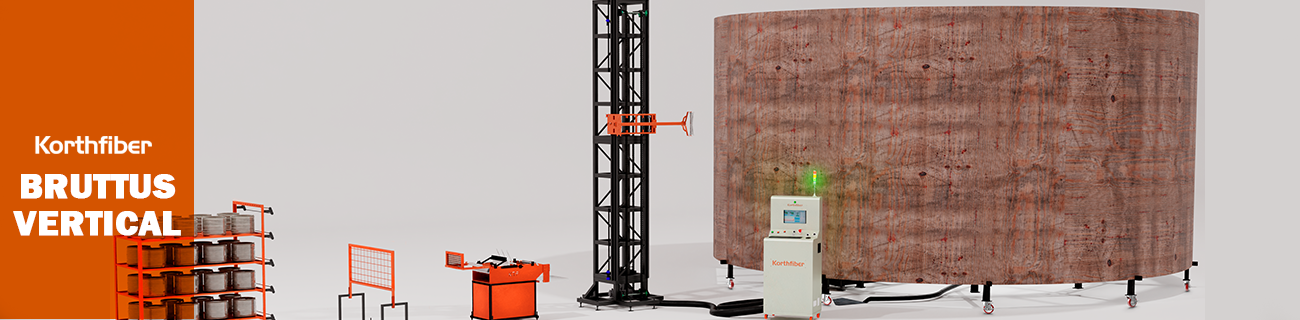

Filament Winding

Equipment for the manufacture of Tanks and Mega Tanks using the Vertical Filament Winding process. One of the biggest advantages is that it can be transported to the Customer’s manufacturing site, avoiding costly freight and other costs.

- Winding speed up to 60 meters per minute (m/min)

- 60-strand Roving Yarn Shelf + 1 Additional Shelf (1P support)

- Manipulating wire passage structure (Wire passage frame - 1 per shelf)

- Wetting tray with Plug And Play system Made in-house with AISI-304 stainless steel

- Wetting of wires by immersion or contact roller

- Control of the amount of resin impregnated in the wire

- Ease of cleaning/access design at the end of winding processes

- NR12 Touch Screen CNC Electrical Control Panel

- Voltage 220 V Three Phase Current 1P 50A

- Real Time Speed Control

- Diameter opening from 12m to 18m

- Frame support for chuck up to 10.0 tons

- Vertical tank manufacturing system

- Expandable arm for manufacturing mega tanks

- Shelf tensioner

| Manufacturing process: | Filament winding |

| Production: | Large diameter tanks |

| Axes: | 2 - Carriage (Z) and Chuck (B) |

| Structure: | Modular with Ease of Assembly and Disassembly for transport to the Manufacturing Site |

| Control: | CNC ASPCOD |

| Command: | CNC Local and Remote with Real Time Speed Control |

| Useful area: | Up to 4200 mm Height – Ø 18000 mm |

| Line performance: | 60 meters per minute |

| Voltage: | 220V Three-Phase Current 1P 30A |

| Operators per machine: | 2 operators |

| Guarantee: | 1 year |

Have a tank, pole or tube factory with the best equipment

of the company recognized worldwide for its excellence.

Speak to an expert: